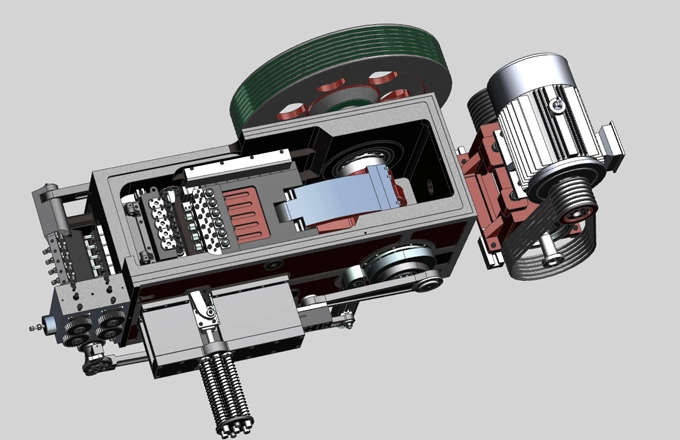

Selection Criteria for Cold Heading Machine

When selecting a cold heading machine, several key factors must be considered to ensure long-term stable operation and efficient production:

High Wear-Resistant Alloy Materials to Enhance Durability

The crankshaft, machine body, and impact connecting rods of the cold heading machine are typically cast from high-wear-resistant alloys, offering high tensile strength and excellent wear resistance. This material effectively increases the lifespan of the cold heading machine, reduces equipment wear, and ensures stable production performance.

Variable Frequency Drive to Enhance Work Efficiency

A cold heading machine equipped with a variable frequency drive can precisely adjust the speed according to production requirements, ensuring that the machine provides high torque and efficiency under different operating conditions. This meets the demands of various processing needs.

Cutter Bar Design for Powerful and Stable Performance

The cutter bar design of the cold heading machine uses linear transmission cutting force, ensuring both power and stability with excellent dynamic balance. This design guarantees stability and precision during the machining process, thereby improving product quality.

Multi-Station Cold Heading Machine to Optimize Forming Processes

A multi-station cold heading machine uses a clamping mechanism to transport workpieces, facilitating reasonable arrangement of the forming processes. Multiple stations can simultaneously perform different tasks, further enhancing production efficiency.

Three-Tier Maintenance System for Cold Heading Machine

To ensure the long-term, high-efficiency, and stable operation of the cold head machine, companies should establish a comprehensive maintenance system, typically following a three-tier maintenance structure. This system ensures effective implementation of daily maintenance, upkeep, and repairs:

Daily Maintenance

Operators are responsible for daily inspections and maintenance of the cold heading machine to ensure that the equipment remains in optimal working condition during production.

Primary and Secondary Maintenance

Primary maintenance involves regular checks on various components of the cold head machine, timely cleaning, and lubrication. Secondary maintenance requires more in-depth inspection and upkeep, such as checking critical components like gears and the lubrication system, to ensure the machine operates precisely.

Mandatory Repairs and Regular Inspections

The three-tier maintenance system emphasizes a mandatory repair system led by the operators. Different maintenance cycles should be developed according to the equipment and working conditions, with strict adherence to these schedules. Additionally, companies should conduct self-inspections and mutual inspections to ensure that every cold head machine is in excellent working condition.

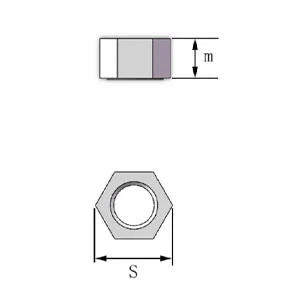

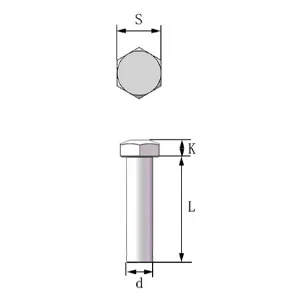

As an essential piece of equipment in modern manufacturing, the cold heading machine is widely used in the production of fasteners such as nuts and bolts, thanks to its high efficiency, low energy consumption, and high precision. When selecting a cold head machine, it is crucial to consider factors like durability, production efficiency, and safety. At the same time, establishing a comprehensive maintenance system will ensure that the machine remains reliable and continues to create value for the business over the long term.

(1).webp)

English

English