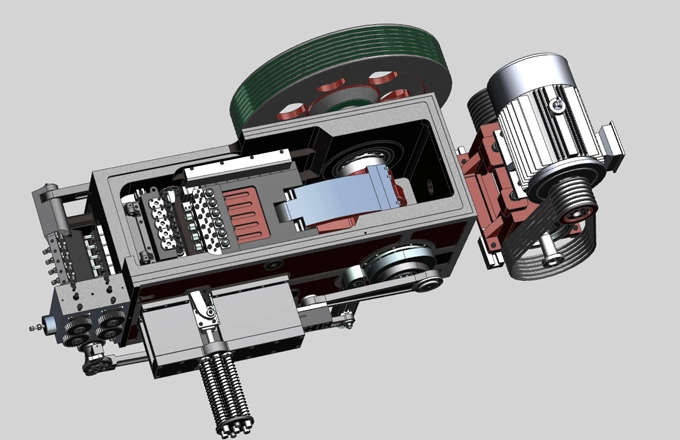

Nut cold forming machine, as a key piece of metal forming equipment, is widely used in the production of nuts and other fasteners. These machines employ cold extrusion technology, allowing metal materials to undergo plastic deformation at room temperature to produce high-strength, high-precision nuts. During the nut cold forming process, several common techniques are used, each with its unique applications.

Cold Forming Nuts Using Smaller Diameter Wire

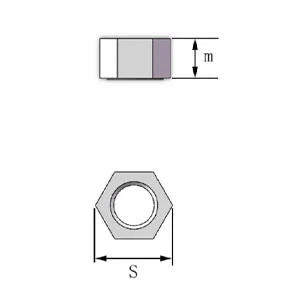

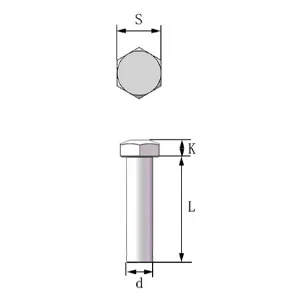

This process is the most common method for nut cold forming. The wire diameter used typically ranges from do = 0.60s to 0.70s, where s is the across-flats size of the nut. The process generally includes several stages such as material cutting, shaping, upsetting, hexagonal pressing, and punching. The nut cold forming machine, with its precision coordination between multiple stations, can efficiently complete these steps.

When used on a three-station or four-station automatic nut cold heading machine, the shaping process can often be omitted, making it suitable for the production of smaller-sized nuts. This method ensures good quality and stability for nuts sized M12 and below. For larger-sized nuts, skipping the shaping step may make it difficult to control the face quality and uniformity. In such cases, other processes are required.

Cold Forming Nuts Using Larger Diameter Wire

This method is suitable for producing larger-sized nuts, especially those sized M12 and above. The wire diameter used is typically do ≈ 0.9s, and it goes through several steps, including cutting, shaping, initial upsetting, pre-forming, fine forming, and punching. This process is generally completed on a five-station automatic nut cold forming machine. The five-station equipment allows for more processing steps, improving production efficiency and ensuring nut precision.

The advantage of this process is its ability to handle larger diameter wire, making it ideal for producing bigger nuts with high production efficiency and yield. The nut cold forming machine plays a crucial role in ensuring the precise coordination of each stage, guaranteeing that the nut's shape and dimensions meet high standards.

Hexagonal Steel Forming Process

The hexagonal steel forming process is less commonly used and is typically applied to the production of large-sized nuts, especially those sized M20 and above. This process is usually carried out on a press machine, utilizing a sequential cold pressing method. The workflow typically includes material cutting, initial pressing, fine pressing, and punching. This technique is suitable for producing large-sized nuts and can ensure shape and dimensional accuracy through gradual forming.

The hexagonal steel forming process offers high production capacity and precision requirements, but it has higher equipment investment and maintenance costs. Therefore, it is mainly used in high-volume production.

Advantages of Nut Cold Forming Machine

Nut cold forming machine offers many significant advantages during the production process. First, they greatly improve the material utilization rate. Compared to traditional cutting processes, cold forming machines effectively reduce material waste, thereby saving costs. Additionally, parts formed by cold forming have higher strength, as the metal fibers remain intact, resulting in mechanical properties far superior to those of cut parts.

Moreover, nut cold forming machine is suitable for high-efficiency, automated mass production, greatly increasing production efficiency. Whether for small or large-sized nuts, the nut cold heading machine plays a crucial role in the production process. By using the cold forming process, nut cold heading machine can efficiently produce nuts that meet precision requirements, widely used in industries such as automotive and machinery. For companies that require mass production of high-precision nuts, the nut cold forming machine is undoubtedly the ideal equipment to improve production efficiency and reduce manufacturing costs.

(1).webp)

English

English