What is a Cold Heading Machine?

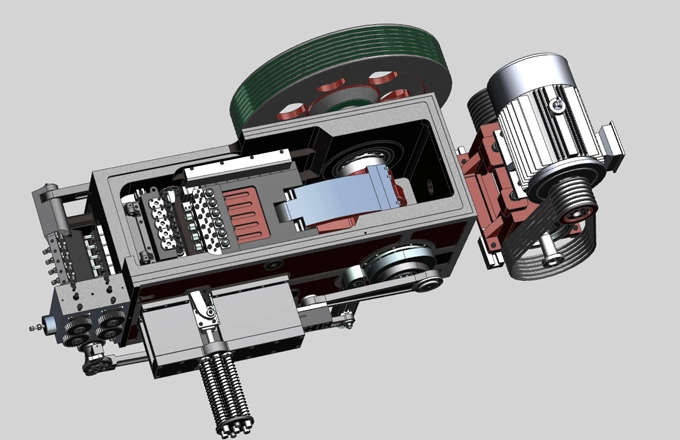

A cold heading machine is a piece of equipment used to process metal materials, widely applied in the production of various metal products such as threads, bolts, screws, and other fasteners. By employing cold extrusion technology, the cold heading machine shapes metal at room temperature, transforming it into the desired form through plastic deformation. In the operation of a cold heading machine, bearings play a crucial role. They are installed at key locations in the machine, such as between the shaft and bearing housing, to reduce friction and support rotating or reciprocating components, ensuring the efficient and stable operation of the machine. The design and material selection of bearings directly affect the performance and lifespan of the cold head machine.

What are the Advantages of a Cold Heading Machine?

The cold heading machine utilizes cold extrusion technology, which is an advanced production process known for its high precision, efficiency, and low energy consumption. It is widely used in the mass production of medium and small-sized forgings. Compared to other machining processes, cold heading machine offers several significant advantages:

High Steel Utilization

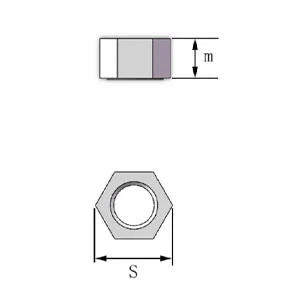

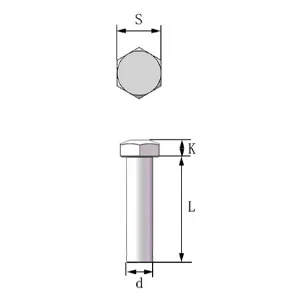

Cold heading (or extrusion) is a process that involves minimal or no cutting. For instance, when producing hex-headed bolts or cylindrical-headed internal hexagon screws, traditional cutting methods typically result in a steel utilization rate of only 25% to 35%. However, when the cold heading (extrusion) method is employed, the steel utilization rate can reach 85% to 95%, significantly reducing material waste and cutting costs.

Excellent Mechanical Properties

Parts processed by cold heading machine have superior strength compared to those made through cutting, as the metal fibers are not severed during the process. Cold heading (extrusion) improves the strength and toughness of the components through plastic deformation of the metal, ensuring the long-term durability of the product.

Ideal for Automated Production

Cold heading machine is particularly well-suited for mass production, especially for producing symmetrical parts like fasteners (including some special-shaped parts). This production method enables high-efficiency automated operations, making it a primary choice for large-scale manufacturing in modern factories.

Increased Labor Productivity

By replacing traditional cutting processes with cold heading machine, not only is production efficiency improved, but the stability and consistency of the production process are also enhanced. Productivity can increase several times, or even dozens of times, significantly boosting the manufacturing capacity of companies.

Optimal Surface Finish and Dimensional Accuracy

Parts processed with cold heading machine can achieve a dimensional accuracy of IT7 to IT8 grades, with surface roughness ranging from R0.2 to R0.6. This means that most cold-extruded parts do not require additional cutting, thus saving costs on subsequent machining.

As an essential piece of equipment in modern manufacturing, the cold heading machine stands out with its high steel utilization, superior mechanical properties, and automation capabilities. It has become the preferred process for mass production of medium and small-sized components. Whether it's enhancing production efficiency, saving material costs, or improving the mechanical properties of parts, the cold head machine demonstrates unmatched advantages. For manufacturers requiring large volumes of high-quality metal parts, the cold heading machine is undoubtedly a vital tool for boosting productivity and competitiveness.

(1).webp)

English

English