1. Introduction: The “Chip-less” Revolution in Manufacturing

Cold heading is not just a manufacturing method—it is the backbone of modern fastener production. If you’ve ever sourced bolts, nuts, or screws at scale, cold heading is the process behind almost every high-strength, cost-efficient part.

At its core, cold heading is a metal forming process that shapes wire into finished components at room temperature, using extreme mechanical force and precision dies. Unlike machining, no material is cut away. Instead, the metal flows into shape.

Why manufacturers choose cold heading manufacturing over other methods:

Near-Zero Waste: Almost 100% material utilization

Superior Strength: Continuous grain flow creates work-hardened parts

High Productivity: Modern cold heading forming machines can produce 50–300 parts per minute

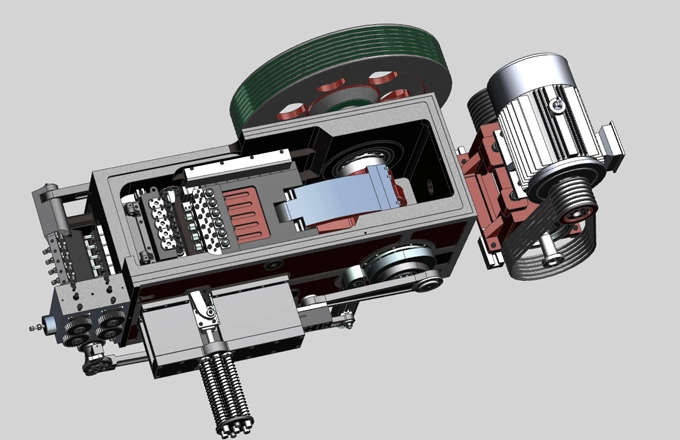

Achieving this level of efficiency and consistency requires highly rigid, precisely engineered equipment—such as BOYU cold heading forming machines, designed specifically for long-term, high-volume production.

2. The Step-by-Step Cold Heading Manufacturing Process

(Keyword focus: Cold heading manufacturing)

From raw wire to finished fastener, the cold heading manufacturing process follows a tightly controlled sequence. Even minor inconsistencies at one stage can affect dimensional accuracy, tool life, and final strength.

Typical process flow: Wire → Shearing → Die 1 → Die 2 → Multi-Blow Forming → Ejection

Step 1: Wire Preparation & Straightening

Cold heading begins with CHQ (Cold Heading Quality) wire, commonly made from:

The wire must have uniform diameter, controlled surface quality, and consistent mechanical properties. It is straightened and fed continuously into the machine to ensure stable forming conditions.

Step 2: Shearing (Cutting the Blank)

The machine cuts the wire into precise lengths, known as blanks or slugs.

Expert insight: The volume of the blank directly determines the final part geometry. Variations as small as ±0.05 mm can cause underfills, flashing, or excessive die stress.

High-end cold heading forming machines use synchronized feeding and shearing systems to maintain extreme consistency at high speeds.

Step 3: Upsetting & Forming (The “Blows”)

This is where the real shaping happens.

Upsetting: Shortens the blank while increasing its diameter—typically forming the bolt head or nut body.

Extrusion: Forces metal to flow through a die opening, either reducing diameter or creating internal features.

Multiple controlled “blows” allow the material to flow gradually, preserving grain structure and preventing defects such as cracks or cold shuts.

Step 4: Ejection

Once forming is complete, knock-out pins eject the finished part from the die, and the cycle immediately repeats—often several hundred times per minute.

3. Nut vs. Bolt: Understanding the Machine Differences

(Keyword focus: nut cold forming machine, bolt header machine)

Although nuts and bolts may look similar to the end user, they require fundamentally different forming mechanics. Understanding this distinction is critical when selecting the right cold heading forming machine.

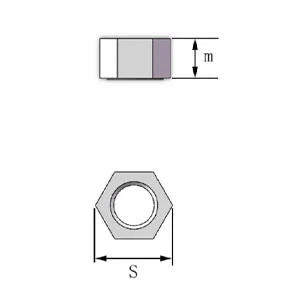

Nut Cold Forming Machines: Short & Stout Parts

Primary Process: Reverse extrusion (piercing the internal hole)

Typical Machine: BOYU Six Die Six Blow Nut Forming Machine

Mechanism: Short stroke lengths with turn-over systems to form both faces

Key Specifications: Width across flats typically 9–58 mm

In nut forming, metal flows backward around a punch to create the internal bore, while multiple dies ensure accurate hex geometry and surface finish.

Learn more about BOYU's nut cold forming machine.

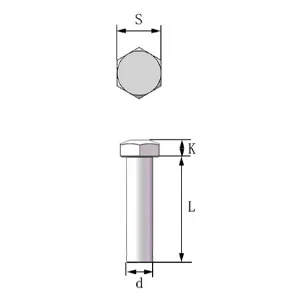

Bolt Header Machines: Long & Thin Parts

Primary Process: Forward extrusion and head upsetting

Typical Machine: BOYU Three-Die / Four-Die Bolt Header Machine

Mechanism: Long stroke length to accommodate extended shank lengths

Capacity: Shank lengths up to 300 mm or more

Bolt headers focus on maintaining straightness, concentricity, and tensile strength, often feeding directly into a thread rolling machine for final processing.

Explore BOYU's bolt header machine solutions.

4. Beyond Basics: What Is a Parts Former?

(Keyword focus: cold heading forming machine)

Many buyers encounter the term “Parts Former” and wonder how it differs from a standard header.

A Parts Former is a multi-station cold heading forming machine—typically 5-die or 6-die—designed for complex, non-standard components.

What makes parts formers unique?

Multiple upsets in a single pass

Combined piercing, extrusion, and trimming

Tight tolerance control across several forming stages

Typical applications

See BOYU's Parts Former machines.

5. Technical Challenges & How Quality Machines Solve Them

Challenge 1: Galling & Tool Wear

High friction between dies and material can dramatically shorten tool life.

Solution: BOYU machines use high-rigidity cast frames and precision oil lubrication systems that reduce friction, control heat, and extend die service intervals.

Challenge 2: Concentricity Issues (Off-Center Heads)

Poor alignment leads to head wobble, rejected parts, and downstream threading problems.

Solution: Advanced ram guidance and die block alignment systems—such as those used in the 41B6S-300L—maintain precise coaxial movement throughout the forming cycle.

Challenge 3: Cold Shuts & Cracks

Sudden material flow can cause folding or internal cracks.

Solution: Multi-blow sequences (e.g., Six Die Six Blow) allow gradual metal redistribution, significantly reducing stress concentration and defect rates.

6. Cold Heading vs. Machining vs. Hot Forging

| Feature | Cold Heading | Machining | Hot Forging |

|---|

| Material Waste | < 5% (Scrap-less) | High (Chips removed) | Moderate (Flash) |

| Production Speed | High (50–300 ppm) | Low | Low–Medium |

| Part Strength | Very High (Work hardened) | Moderate (Grain cut) | High |

| Cost (High Volume) | Lowest | High | Moderate |

| Best For | Bolts, nuts, screws | Low-volume custom parts | Very large fasteners (>M30) |

7. Conclusion: Choosing the Right Cold Heading Partner

Cold heading manufacturing remains the most efficient, strongest, and most economical method for producing fasteners at scale. But the process is only as good as the machine behind it.

Whether you need a high-speed nut cold forming machine, a long-stroke bolt header machine, or a flexible parts former, choosing equipment with proven rigidity, precision, and durability is essential.

With 30+ years of engineering experience, Wenzhou BOYU Machinery Co., Ltd. continues to support manufacturers worldwide with reliable cold heading solutions built for real production demands.

(1).webp)

English

English