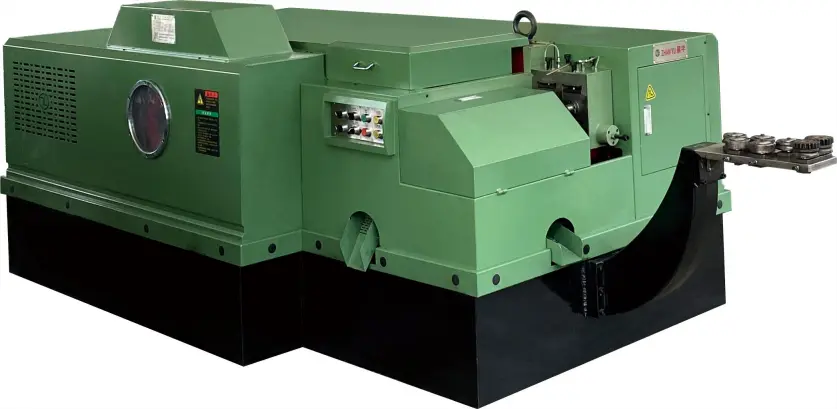

How to Set up a Six Die Six Blow Nut Cold Forming Machine?

Setting up a six-die six-blown nut cold forming machine—an advanced nut cold forming machine— involves several key steps to ensure accurate and efficient operation of this nut cold forming machine. First, load the appropriate wire or bar stock into the wire feeder of the nut cold forming machine. Next, adjust the six die molds and punches of the nut cold forming machine to the desired size, ensuring they are properly aligned and securely fixed for the nut cold forming machine’s optimal performance. Configure the nut cold forming machine's settings, such as stroke length and feed rate, to match the specific hex nut size and shape you intend to produce with this hex nut making machine. The nut cold forming machine manual typically provides detailed setup procedures for the nut cold forming machine, including safety checks and calibration steps tailored to the nut cold forming machine. Strict adherence to these guidelines is essential for achieving optimal performance and product quality from the nut cold forming machine.

The Best Nut Cold Heading Machine for Sale

Looking for a nut cold heading machine for sale? Boyu Machinery offers top-quality, efficient, and durable nut cold heading machines designed for precision and high productivity. Our machines are perfect for manufacturing nuts of various sizes, catering to industries that demand reliability and performance.

At Boyu Machinery, we pride ourselves on delivering advanced solutions to meet your needs. Each nut cold heading machine—whether you choose our Nut Cold Heading Machine for Sale or general cold heading machine for sale— is crafted with innovative technology, ensuring smooth operation and cost-effective production. Whether you are in the automotive, construction, or hardware industry, our machines can help streamline your production process.

Benefits of Using an Automatic Nut Cold Forming Machine for Precision Manufacturing

When it comes to precision manufacturing, investing in advanced equipment like the automatic nut forming machine is a game-changer. These cold forming machines streamline production processes, ensuring consistent quality and reducing manufacturing time. At Boyu Machinery, our nut cold forming machines are designed to meet the needs of modern production facilities with unparalleled efficiency and accuracy.

Key Benefits of Automatic Nut Forming Machines:

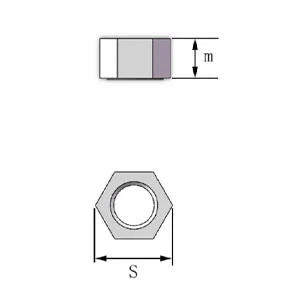

Enhanced Precision: Automatic nut forming machines allow for the creation of high-quality nuts with exact dimensions, meeting the strict requirements of industries such as automotive, aerospace, and construction.

Cost-Efficiency: By minimizing material waste and accelerating production cycles, these machines lead to significant cost savings over time.

Increased Productivity: The fully automated system eliminates manual intervention, enabling manufacturers to produce a higher volume in less time without compromising quality.

Durability and Reliability: Our nut cold forming machines are engineered using high-grade materials, ensuring long-term performance even under high-stress production conditions.

Customization Options: Boyu Machinery provides advanced machine configurations that cater to diverse manufacturing needs, giving you full control over product customization.

Applications of Nut Cold Heading Machines in the Fastener Industry

Boyu Machinery specializes in crafting high-quality nut cold heading machines, revolutionizing efficiency and precision in the fastener industry. These machines play a pivotal role in manufacturing durable nuts used across diverse applications, including automotive, construction, electronics, and heavy machinery.

Key Applications of Nut Cold Heading Machines:

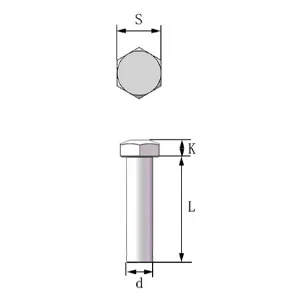

Automotive Industry: Ensure the production of strong, reliable fasteners that meet stringent quality standards for vehicles.

Construction Sector: Create heavy-duty nuts required for structural integrity in buildings and infrastructure projects.

Electronics: Produce compact, precision-engineered nuts for delicate electrical assemblies.

Industrial Machinery: Manufacture high-performance fasteners designed for heavy equipment and machinery.

With cutting-edge technology, Boyu Machinery's nut cold heading machines optimize production speed while minimizing material waste, ensuring cost-effective and consistent manufacturing. Boyu Machinery also provides bolt cold heading machines for the automotive industry, aerospace sector, electronics manufacturing, and more.

(1).webp)

English

English