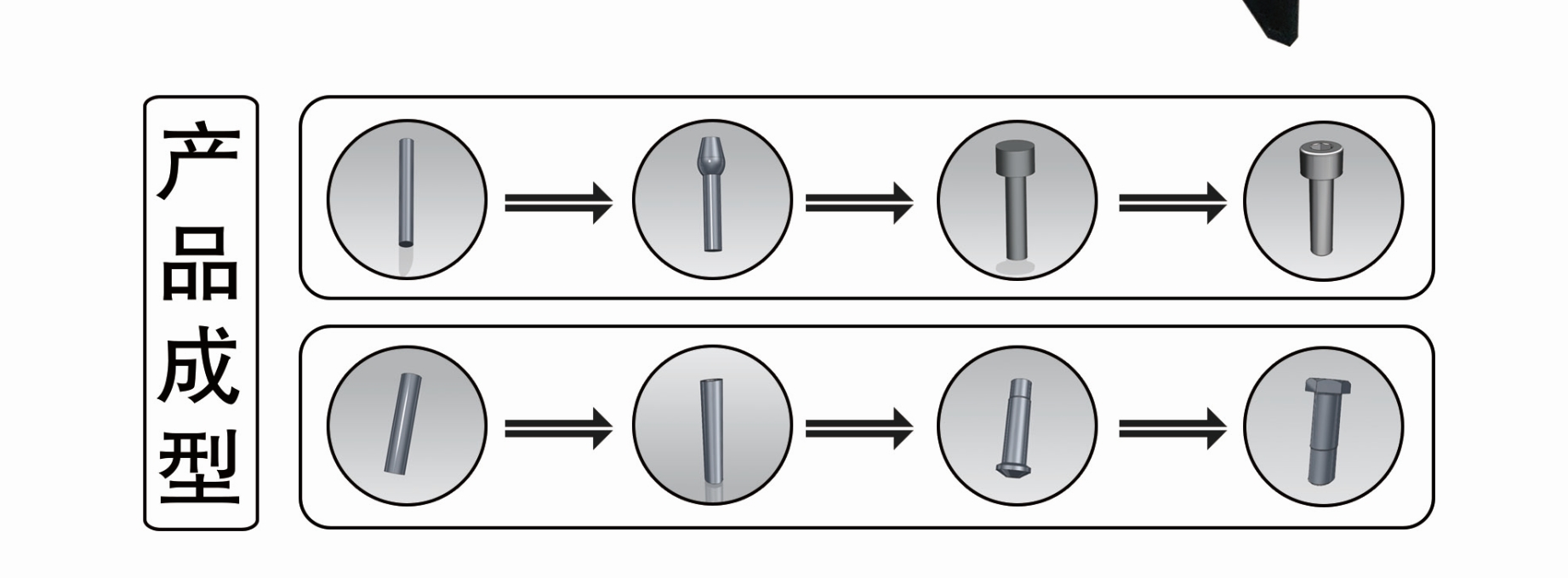

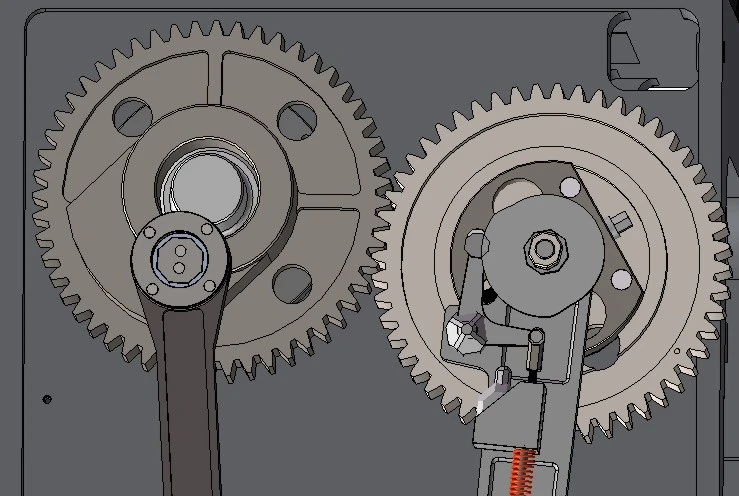

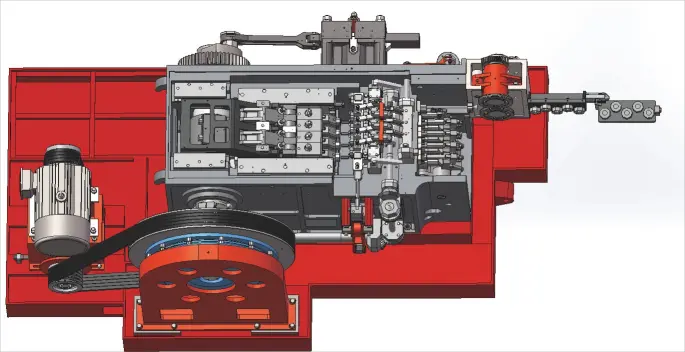

The six-die six-stroke nut cold heading machine is an ideal machine for producing nut fasteners. Alongside its efficiency, manufacturers often use a bolt header machine in combination with this equipment to expand production capabilities. Due to the short stroke of the machine slide and the high production speed, large-scale production in a short time can bring good profits, especially when both nut and bolt production are optimized within the same facilities.

What is the Difference Between a Barrel Bolt and a Tower Bolt?

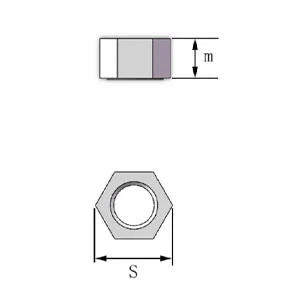

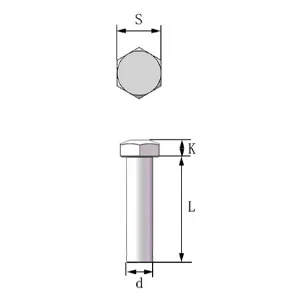

Barrel bolts and tower bolts may appear similar but serve distinct purposes in securing doors and windows. A barrel bolt is a cylindrical fastener mounted on gates or doors for added security, utilizing a straight sliding bolt. On the other hand, a tower bolt offers a more robust design with greater durability, making it an ideal choice for heavy-duty applications. Tower bolts are extensively used in modern homes, providing dependable locking mechanisms.

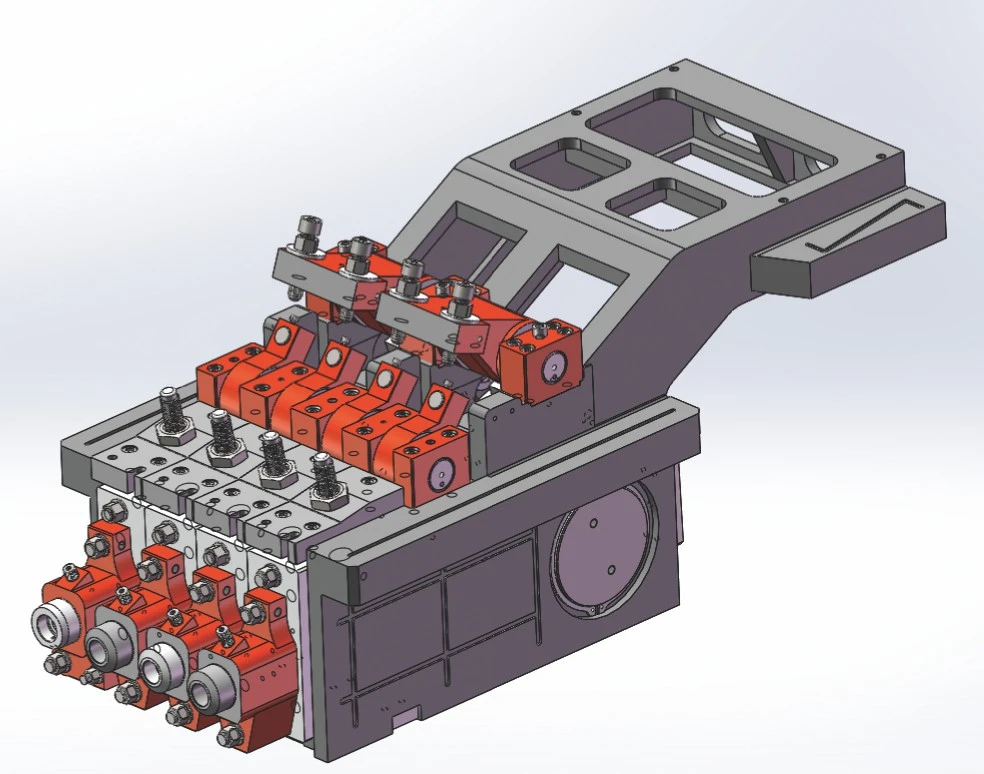

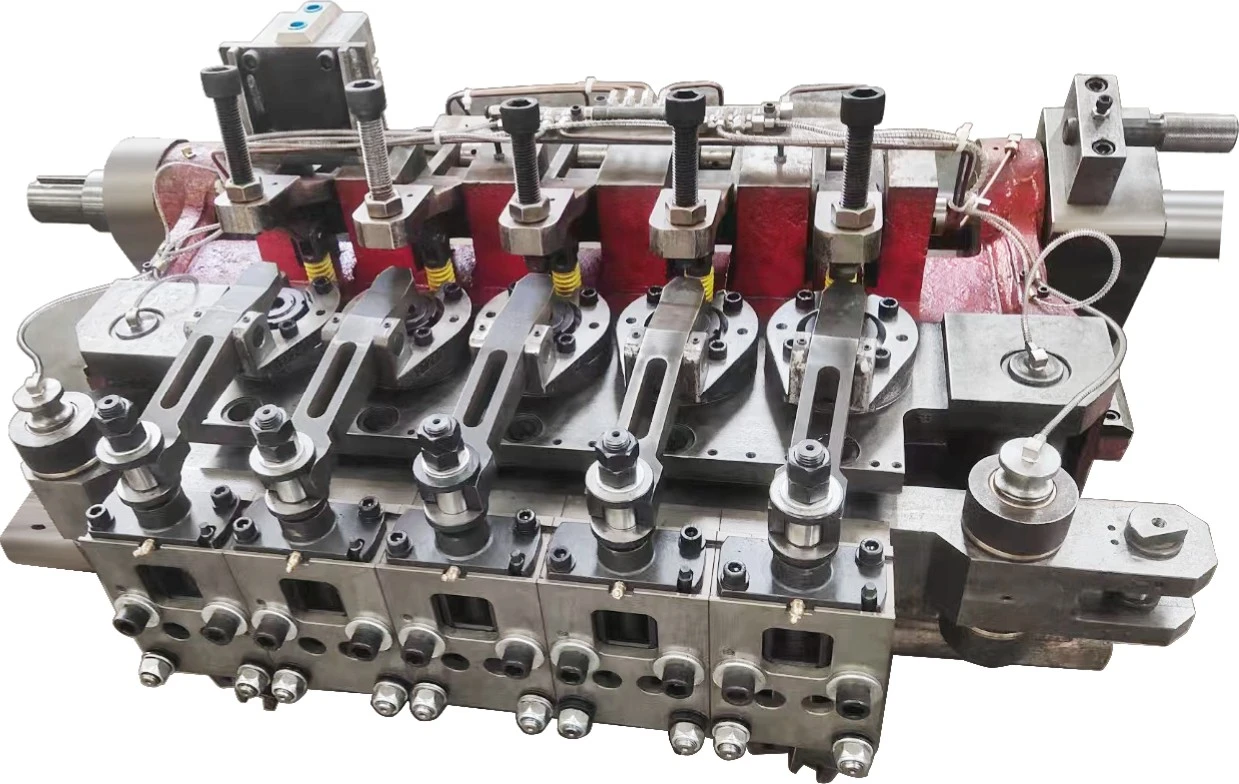

At BOYU Machinery, we specialize in manufacturing state-of-the-art tower bolt making machines designed for precision and efficiency. Whether you're producing industrial-grade tower bolts or heavy-duty fasteners, our innovative machinery ensures exceptional quality with every batch.

(1).webp)

English

English.webp)

.webp)

.webp)

.webp)